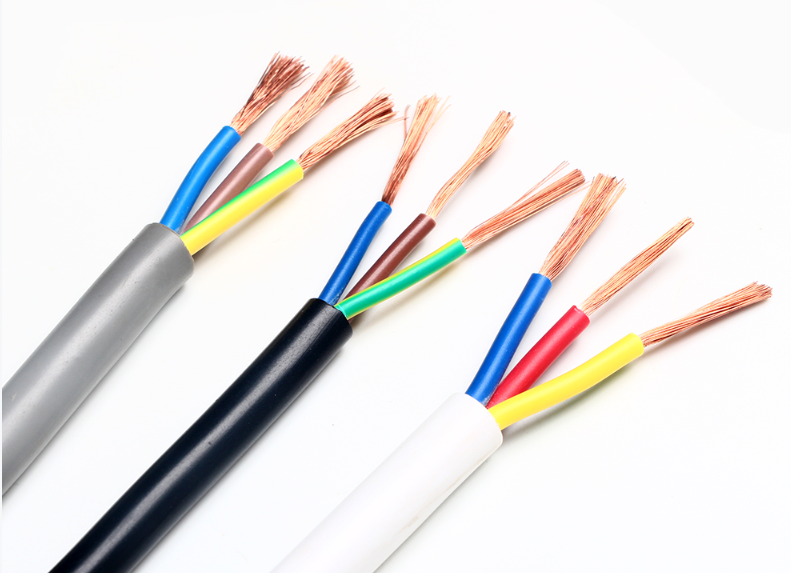

What is the relationship between the thickness of the outermost sheath of the common sheath line and the quality of the inner cable?

2022-08-15 17:22Standard relation of cable sheath thickness

Sheath line if the thickness of the sheath is lower than the national standard requirements, of course, it is not qualified, but if the outermost thickness of the sheath line exceeds the national standard requirements, it is also not qualified. Just like the control cable KVVP 3*1.5 square sheath line, the average thickness of the sheath is 0.8mm. If this model refers to the national standard, the thickness should be 1.1mm. The reasons for disqualification are as follows:

1, reduce the service life. After the cable is laid, it will be energized for a long time, and the sheath line will often generate heat. The permissible operating temperature of the conductor is 70°C. The long-term service temperature of PVC sheath line should not exceed 65℃.

If it is in summer, the working temperature will rise, and these temperatures will be distributed through the external sheath. The sheath thickness will increase, and the heat energy will be difficult to be distributed, affecting the service life of the cable. Due to the action of heat, the insulation layer of the cable has undergone physical and chemical changes, and the sheath line has lost its original excellent performance, leading to a significant decline in insulation performance, and even a short circuit, affecting the normal operation of the unit.

2, sheath line material performance defects. Material properties are not reflected in thickness. Based on the requirements of national standards,

If one indicator of the sheath line does not meet the standard, flame retardant PVC material, then its oxygen index is below 30.

3. There are problems with the structure of the sheath line. If it is in summer, the working temperature will rise, and these temperatures will be distributed through the external sheath. The sheath thickness will increase, and the heat energy will be difficult to be distributed, affecting the service life of the cable. Due to the action of heat, the insulation layer of the cable has undergone physical and chemical changes, and the sheath line has lost its original excellent performance, leading to a significant decline in insulation performance, and even a short circuit, affecting the normal operation of the unit.

2, sheath line material performance defects. Material properties are not reflected in thickness. Based on the requirements of national standards,

If one indicator of the sheath line does not meet the standard, flame retardant PVC material, then its oxygen index is below 30.

3. There are problems with the structure of the sheath line. If the conductor cost, insulation layer and weaving density are controlled according to national standards, and suitable fillers are chosen to make them round, how can the outer sheath of the cable be squeezed so thick? According to the requirements of national standards to control the cost of conductors, insulation layer and weave density, and choose the right filler to make them round, so how can the outer sheath of the cable be squeezed so thick?

4. Increase the difficulty of cable laying. At present, cable laying is mainly based on Bridges or pipelines. Now many enterprises are implementing strict cable requirements and small outside diameters. In the process of laying, the sheath line can leave a gap to emit heat energy to ensure that the outer sheath of the cable is not damaged. Otherwise, it will be handed over to the construction unit. And the laying of cables brings certain difficulties.

According to the above, the thickness of the cable sheath should be controlled according to the national standard, which is what the cable enterprise should do, not only for the enterprise to save the sheath line resources, reduce material consumption, increase profits, and ensure the quality of the cable, to create high quality and low price products.

Ok, so that's about "What is the relationship between the thickness of the outermost sheath of a common sheath line and the quality of the inner cable?" The introduction, hope to help you! It is recommended to continue to pay attention to Ruiyang cable for more information about sheath cable.